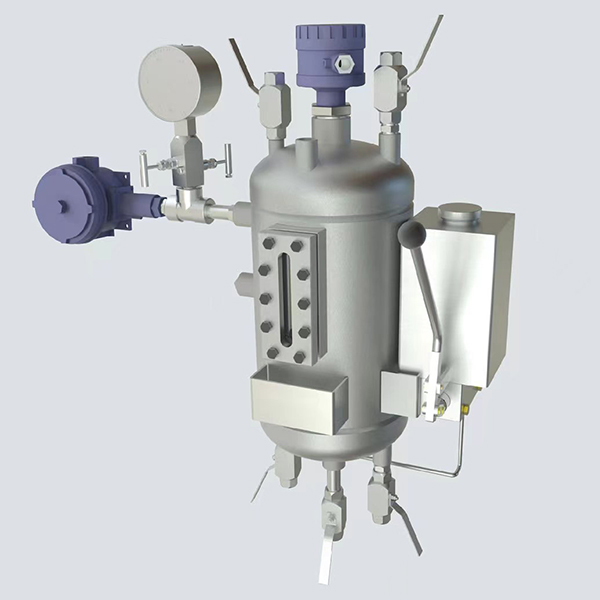

Operating parameters:

Temperature: -20 ℃~200 ℃

Pressure: ≤ 2.5MPa

Rotational speed: (no rotational speed added volume and heat dissipation area) Volume: 6-18L Heat dissipation area: 0.1-0.3 ㎡

Structural features: Plan52: Usually used for non pressurized double end mechanical seals. Under normal circumstances, circulation is maintained through the pump efficiency ring inside the pump. The balance tank provides sealing fluid for mechanical seals, and the pressure inside the tank is lower than the pressure in the sealing chamber. Plan53A: Usually used for pressurized double face mechanical seals, under normal circumstances, circulation is maintained through the pump efficiency ring inside the pump, and nitrogen layer is used for pressurization. The balance tank provides sealing fluid for mechanical seals, and the pressure inside the tank is higher than the pressure in the sealing chamber. Plan53B: Usually used for pressurized double face mechanical seals, under normal circumstances, circulation is maintained through the pump efficiency ring inside the pump, and pressurized using an airbag accumulator. The balance tank provides sealing fluid for mechanical seals, and the pressure inside the tank is higher than the pressure in the sealing chamber

Application condition: Suitable for mechanical sealing of vertical stirring kettle rotary shaft, providing sealing fluid for it