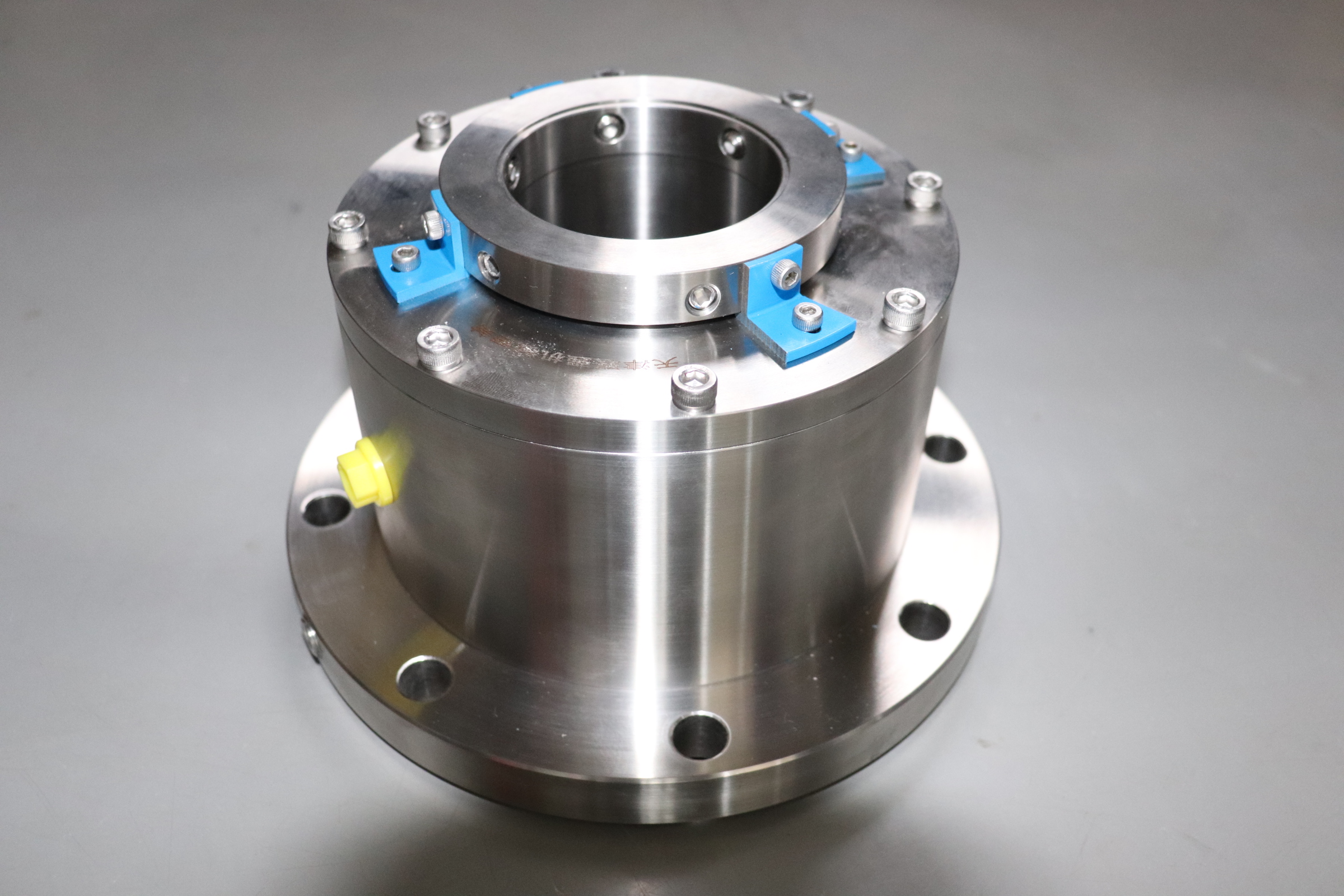

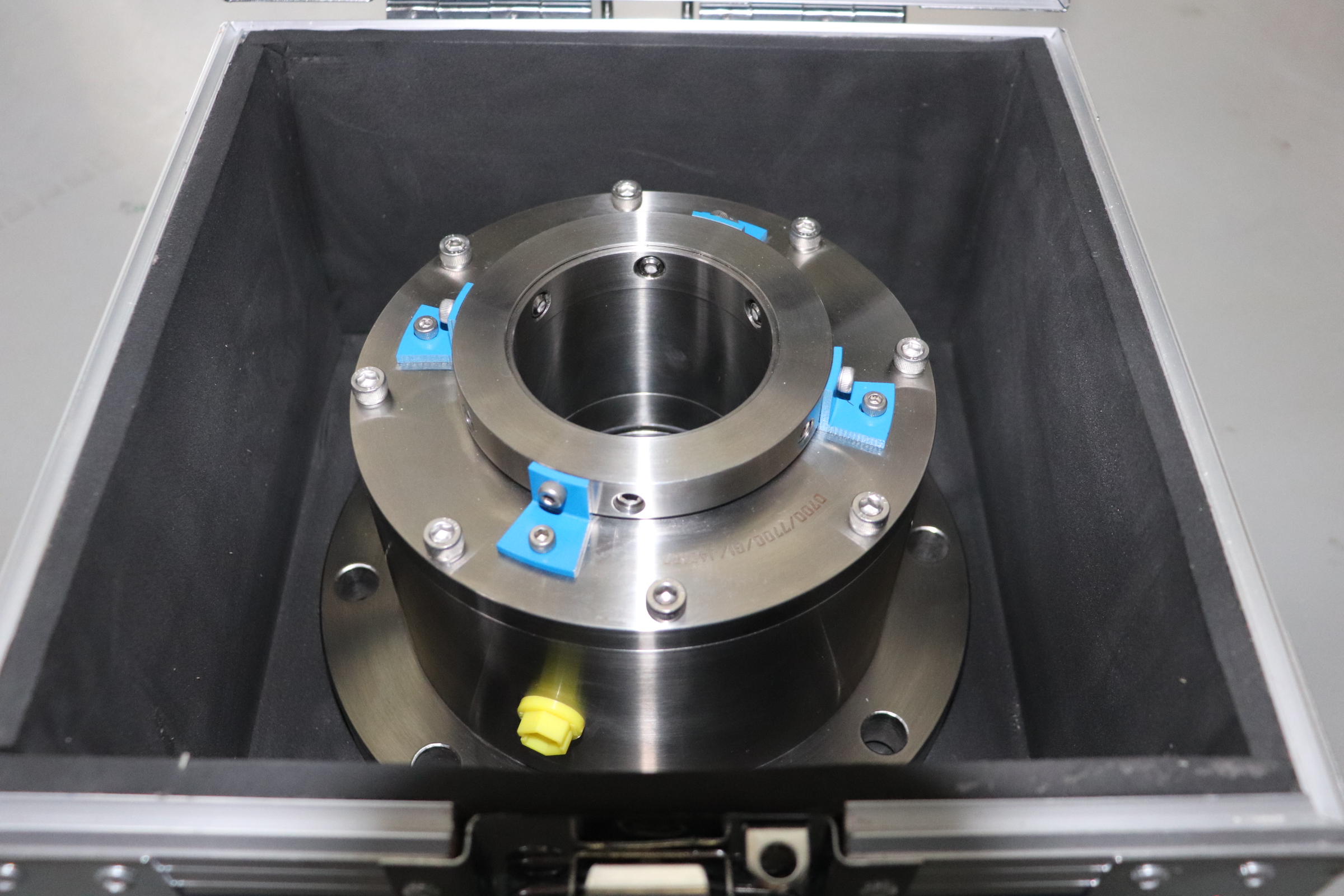

Mechanical seal refers to a device that prevents fluid leakage, consisting of at least one pair of end faces perpendicular to the rotational axis that adhere and slide relative to each other under the action of fluid pressure, compensation mechanism elasticity (or magnetic force), and auxiliary seals.

Mechanical seal is a shaft sealing device for rotating machinery. For example, equipment such as centrifugal pumps, centrifuges, reactors, and compressors. Due to the transmission shaft penetrating inside and outside the equipment, there is a circumferential gap between the shaft and the equipment, through which the medium in the equipment leaks outward. If the pressure inside the equipment is lower than atmospheric pressure, air leaks into the equipment. Therefore, there must be a shaft sealing device to prevent leakage. There are many types of shaft seals, and due to the advantages of low leakage and long service life, mechanical seals are the most important shaft sealing method in these equipment worldwide. Mechanical seals, also known as end face seals, are defined in relevant national standards as follows: "A device that prevents fluid leakage by at least one pair of end faces perpendicular to the rotation axis, under the action of fluid pressure and compensation mechanism elasticity (or magnetic force), as well as the coordination of auxiliary seals to maintain contact and relative sliding

Mechanical seals rely on elastic components to pre tighten the dynamic and static ring end face sealing pairs and compress the medium pressure to achieve axial end face sealing. They can generally be classified into two types: contact type and non-contact type. Their characteristics can be summarized as: reliable sealing, no leakage or little leakage during a long service life, long service life, correct selection of materials and friction surfaces can increase the service life of the mechanical seal, and long maintenance cycle, Friction power loss is relatively low, and it is less sensitive to shaft vibration. It has a wide range of applications and can be used in media such as low temperature, high temperature, low pressure, high speed, flammable, explosive, and toxic according to environmental requirements.

Device composition:

Main components

Dynamic ring, static ring, cooling device, and compression spring (depending on the specific equipment).

Auxiliary seal

Sealing rings (including O-ring, X-shaped, U-shaped, wedge-shaped, rectangular flexible graphite, PTFE coated rubber O-ring, etc.).

Elastic compensation mechanism

Springs, push rings.

Spring seat and key or various screws.

classification

Divided into single end face and double end face; Balanced and unbalanced; Any rotation direction, fixed rotation direction

Device principle:

Mechanical seal is a shaft sealing device that achieves leakage resistance by maintaining a pair or several pairs of opposite sliding faces perpendicular to the shaft under the action of fluid pressure and the elastic (or magnetic) force of the compensation mechanism, and assisting in sealing.

The commonly used mechanical seal structure consists of components such as a stationary ring (stationary ring), a rotating ring (moving ring), an elastic element spring seat, a set screw, a rotating ring auxiliary seal ring, and a stationary ring auxiliary seal ring. The anti rotation pin is fixed on the gland to prevent the stationary ring from rotating.

Rotating and stationary rings are often referred to as compensating or non compensating rings based on whether they have axial compensation capability.

System composition:

Shaft seal box

In the past, the shaft seal box used to hold mechanical seals was designed as a stuffing box for soft packing seals. It is not suitable for holding mechanical seals, not only is the size too small and the gap too narrow, but the simple cylindrical shape is also not suitable.

Foreign countries have formulated standards for large-sized mechanical seal shaft seal boxes. In addition, the United States_ Durami Tailek and the British Fluid Dynamics Research Group are both researching a reasonable mechanical seal shaft seal box. Its shape should not only facilitate fluid flow and heat dissipation, but also facilitate the removal of solid particles, creating a good surrounding environment for the seal.

Control of volatile matter release

In the past, only attention was paid to eliminating visible fluid leaks, without paying attention to controlling the amount of volatile substances that could not be seen, which caused environmental pollution and posed a risk to the device and personnel. Foreign countries such as the Sealing Technical Committee of the American Society of Friction and Lubrication Engineers have developed guidelines for the control of volatile emissions in rotating machinery, compressors, and screw systems with mechanical seals for SP-30 (1994), SP-32 (1990), and SP-33 (1991). SP-30 is implemented in three stages. It clearly defines the definition of blocking fluid and buffer fluid, and clarifies the concepts of errors and confusion. Blocking fluid refers to the fluid that completely blocks the process fluid between two seals and leaks into the surrounding environment. The pressure of the blocked fluid is always higher than the pressure of the sealed process fluid. Buffer fluid is a fluid used as a lubricant or buffer between double seals, and the pressure of the buffer fluid is always lower than that of the sealed process fluid.

Supporting system

In the auxiliary system of mechanical seals, cooling, heating, flushing and other systems need to be matched, pump circulation needs to be optimized, and problems such as status monitoring systems are being studied and solved. The API-682 standard specifies the matching of auxiliary systems.

Gas blockage sealing system

In the past, liquid blocking liquids or liquid blocking gases were commonly used in blocking sealing systems. In order to simplify large blocking liquid systems, blocking gases were used to block liquids or gases. In sealing systems, spiral groove gas seals and blocking gases, floating sleeves and blocking gases were used to block gases and liquids.

Technical requirements:

The sealing ring is the general term for the dynamic and static rings (the same below), and is the most important component that constitutes a mechanical seal. The sealing ring largely determines the performance and lifespan of mechanical seals, therefore, some requirements are put forward for it.

Having sufficient strength and stiffness

Under working conditions (such as pressure, temperature, and sliding speed), it should not be damaged, and deformation should be minimized as much as possible. When working conditions fluctuate, it can still maintain sealing. Especially, the sealing end face should have sufficient strength and certain corrosion resistance to ensure a satisfactory service life of the product.

Has good heat resistance and impact resistance

Therefore, it is required that the material has a high thermal conductivity and a small coefficient of linear expansion, so as not to crack when subjected to thermal shock.

Smaller friction coefficient

The matching of sealing rings should have a small coefficient of friction.

Good self-lubrication

If short-term dry friction occurs during work, it will not damage the sealing end face. Therefore, the sealing ring should have good self-lubrication, and the sealing ring material and sealing fluid should also have good wettability.

Simple structure

The sealing ring structure should strive to be simple and symmetrical, and priority should be given to using an integral structure. Combination (such as embedded) sealing rings can also be used, and the use of sealing end face spray coating structure should be avoided as much as possible.

The sealing ring should be easy to process and manufacture

Installation and maintenance should be convenient, and the price should be low.

Fault cause:

The faults of mechanical seals are generally only known to people after the occurrence of abnormal leakage, abnormal wear, abnormal torque, and other phenomena. There are generally four reasons for the malfunction:

1. The design and selection of mechanical seals are incorrect;

2. Poor mechanical seal quality;

3. The accuracy of the machine using or installing mechanical seals cannot meet the requirements;

4. Machine operation error.

Application scenario:

Mechanical seals are widely used in various fields both domestically and internationally, such as petrochemical, oil and gas transportation, nuclear power, electricity, hydropower, pharmaceuticals, metallurgy, food, shipbuilding, aerospace, and so on